RC Inject 300 instructions (version 1.2)

Instructions RC- Inject 300®

Substrate preparation

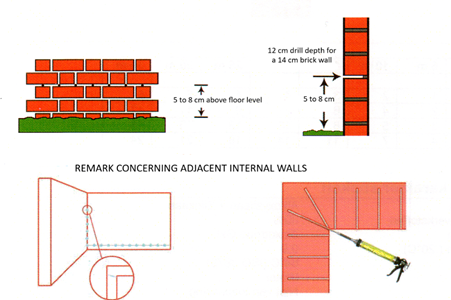

Remove plints and paneling. Remove all affected plaster up to the level of the layer to be treated. If earlier a treatment against rising damp was carried out with another product then drill the holes for RC-Inject 300® about 5 or 8 cm higher than the old holes. If there is an old horizontal dampproof layer present -e.g. bituminous or plastic- then remove all plaster under this layer and inject RC-Inject 300® under the old dampproof layer. Inject as close as possible near floor level or on plint level. Never inject under the floor/garden level.

Drilling

Drill horizontal holes with a diameter 12 to 14 mm in the wall with an in-between distance of 10 to 12 cm and under an angle of 15° to 30°. Set drill depth with your drilling machine or put some tape on the drill to ensure needed depth which is depending on the wall thickness (see table below).

Between injected walls and adjacent walls not needing treatment a vertical layer should be applicated with a minimum -height of 120 cm and at least 50 cm above the wall humidity and salts (efflorescences). Inside corners should be drilled slanted. Distance between the holes : 10 to 12 cm.

| Wall thickness | Drilling depth |

| 9 cm | 7 cm |

| 14 cm | 12 cm |

| 19 cm | 17 cm |

| 29 cm | 27 cm |

| 40 cm | 37 cm |

| 50 cm | 47 cm |

° massive inside or outside walls : drill/inject only one side

° cavity walls : inside and outside to be injected separately

° natural stone walls : inject if porous (limestone

Tools

- Pull out the piston from the injection gun at maximal length

- Un screw injection pistol head and insert the 600 ml cartridge RC-Inject 300

- Cut off the end of the cartridge and close the injection gun

Injecting

Insert the injection needle up to the end of the hole and retreat slowly a few cm. Gently squeeze the gun lever and fill the hole completely with RC-Inject 300® while gradually retracting and stopping 1 cm before wall surface. Drilled holes should be closed subsequently with hydrophobing mortar.

Consumption

Number of 600 ml cartidges

| Wall length | 5 m | 10 m | 15 m | 20 m | 25 m | 30 m |

| Wall thickness | ||||||

| 10 cm | 1 | 2 | 3 | 4 | 4 | 5 |

| 20 cm | 2 | 4 | 6 | 7 | 9 | 11 |

| 30 cm | 3 | 5 | 8 | 10 | 13 | 15 |

| 40 cm | 4 | 7 | 11 | 14 | 18 | 21 |

TECHNICAL CHARACTERISTICS

| Active materiale | 80% |

| Type des bases | mixture alcoxysilane / siloxane |

| Solvents | water |

| Density | 0,9 |

| Aspect | Thixotropic gel |

| pH | / |

| Flash point | 64°C (ISO 3679) |

| Color | white |

Safety

Consult most recent Material Safety Datasheet.

Remark

Even if a wet wall has been treated correctly against rising damp it will take long to dry out. Average one has to consider 1 month drying per 2 cm wall thickness. This will also depend on the nature and the initial humidity level of the wall. In practice the durability of this system is unlimited. It is the most flexible and polyvalent system on the market. It is only little destructive and can be used for all masonry. Its application is quick and easy. Do not applicate under 5° C (ambiant temperature and surface temperature). Efflorescence problems or salts already present in the wall are not cured and can deteriorate the finishing layer. Hygroscopic salts like chlorides and certainly nitrates can keep a wall still wet even after injection against rising damp and should be treated with a suited product.

Tool cleaning and accidental spill

With warm water and a little detergent

Storage and shelflife

Fresh (between 5°C and 25°C) and frost-free in the original packaging.

9 months after production date.

Legal notice

The information given herewith and particularly the recommendations given for the application and final usage relative to the Rwanda Chemicals products have been provided in good faith and based on today’s company knowledge for its products when stored and used as indicated in the technical leaflet. As in practice substrates, specific conditions, etc may vary widely all advice and recommendations given by Rwanda Chemicals substitute no guaranty and customers should be testing compatibility for his specific case before using. No guarantee can apply in case of non conform application. Not respecting the written advice implicates no guarantee other then the legal guarantee against hidden defects. Rwanda Chemicals reserves the right to alter the properties of the product. The rights of third parties imperatively should be respected. All orders are accepted subject our Conditions of sale in force. The user should imperatively consult the most recent version of the Technical datasheet for the corresponding product.